In 2001, I created a customized Weber Smokey Mountain Cooker called The Little Red Bullet as a fundraiser for eBay’s “Auction for America” after the tragic events of September 11. Three years later, I created a second customized cooker called “The Two-Tone Blue Bullet.” This cooker was auctioned on eBay on October 1-11, 2004 to benefit hurricane victims in Florida and neighboring states.

The winning bid of $660 was submitted Thomas R. Markovic of Orlando, Florida. To provide an incentive for bids above the cooker’s value of $582, I personally matched dollar-for-dollar the amount of the winning bid exceeding $582, to a maximum of $500. As a result, my match was $78. My employer at the time, Hewlett-Packard Company, matched the contribution, so that a grand total of $1,476 was raised for the American Red Cross.

The idea behind this project was the same as The Little Red Bullet: To have some fun working on it; to feature the finished product here so you could enjoy it and maybe be inspired to try a project like this yourself; and to donate the value of the cooker to a charitable cause.

Here are some pictures of this one-of-a-kind cooker and a description of the processes and modifications that went into it. I hope you like what you see!

Note: As you read this article, keep in mind that Weber made several changes to the Weber Bullet in 2009 that eliminate the need for some of the modifications described here, specifically adding a thermometer and closing gaps in the charcoal grate.

Introducing “The Two-Tone Blue Bullet”

- A brand new Weber Smokey Mountain Cooker with a two-tone porcelain enamel finish. The lid and charcoal bowl are dark blue/purple; the middle cooking section is medium blue/purple.

- Old-school Weber wooden lid handle with black semi-gloss finish.

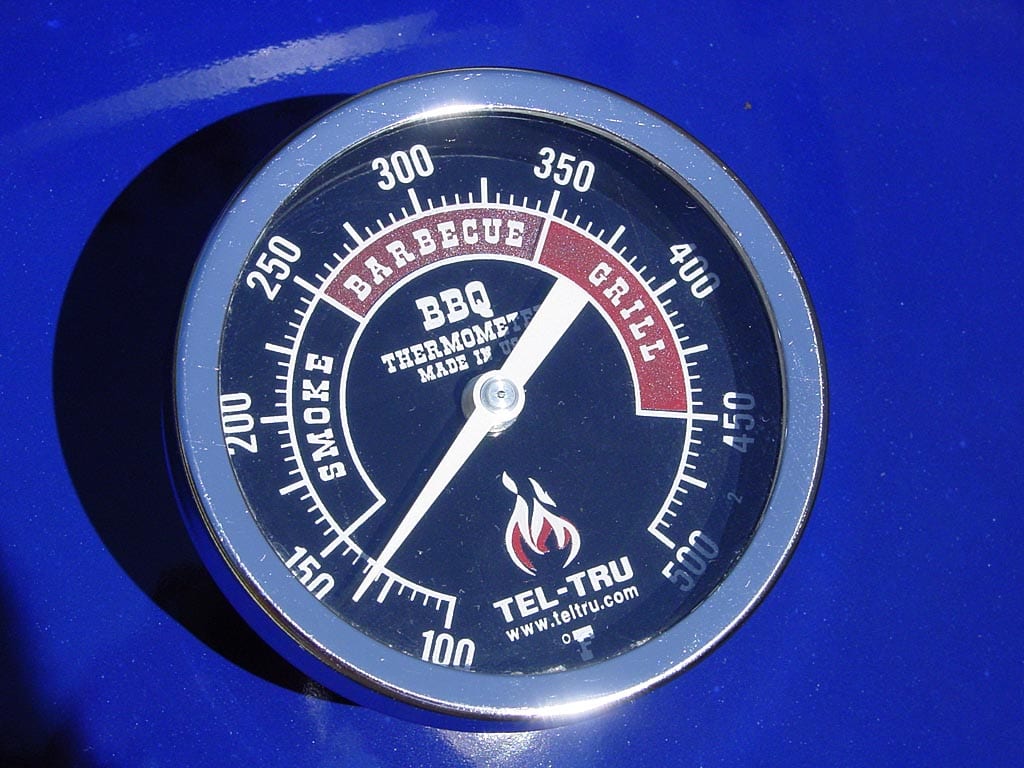

- Tel-Tru BQ300 BBQ Thermometer with black 3″ dial face, 100-500°F range, 2.5″ stem, mounted in the lid.

- Probe thermometer eyelet in middle cooking section.

- Black anodized aluminum legs, access door, and vent dampers.

- Stainless steel inset hex head damper screws with flat black finish.

- All screw heads with flat black finish.

- Modified charcoal grate to prevent charcoal fall-through.

Stripping Down The Cooker

The lid handle and the four vent dampers had to be removed before I could send the parts out for refinishing. The handle was removed by unscrewing the two handle halves. To remove the dampers, I used a 5/16″ metal bit to drill out the inside of each rivet to weaken it, then used a pair of pliers to crush the rivets and pop them out.

I drilled a 3/4″ hole in the lid for the thermometer using a Unibit #4 step drill bit. You can read about how to drill holes in the WSM for thermometers, including an example using a Unibit, on the Installing A Thermometer page.

These photos are from The Little Red Bullet Project, but they represent the same process used on this cooker.

Refinishing The Cooker

Unlike The Little Red Bullet Project, which used a powder coated finish, I wanted a genuine porcelain finish on this cooker. The nearest source I found for this work was located in Southern California.

I shipped the three parts to the refinisher, where they were cleaned, sprayed with porcelain coating on the exterior surfaces, and fired at over 1100°F.

Old-School Weber Wooden Lid Handle

I wish the WSM still came with a wooden lid handle. Fortunately, I had some old, unfinished wooden handles laying around. I sanded the handle and applied several coats of semi-gloss black paint. I especially like the Weber logo stamped into the surface.

Tel-Tru BQ300 BBQ Thermometer

The black dial of this Tel-Tru BQ300 bi-metal BBQ thermometer goes really well with the other black parts on this cooker. One neat feature is that the cooking ranges for smoking, barbecuing, and grilling are indicated on the face.

I placed a large steel washer over the thermometer mounting base, which acts as a spacer between the lid and thermometer, then inserted the thermometer into the hole in the lid and fastened it with an electrical conduit lock nut.

Probe Thermometer Eyelet

This eyelet replaces one of the screws that fastens the grill strap to the inside of the middle cooking section, allowing one or more probe thermometers to be inserted into the cooker. A special flaring tool fastens the eyelet to the cooker.

Special thanks to Fred Pirkle at The BBQ Guru for providing the eyelet for this cooker.

Black Anodized Aluminum Legs, Access Door & Vent Dampers

I had a black anodized finish applied to all the aluminum parts of this cooker.

The parts were cleaned and then placed in an electrically-charged sulfuric acid solution. This causes oxidation—called “anodic film”—to form on the surface of the parts. The process was finished by sealing the pores of the anodic film using a hot water bath.

The anodizing process improves the appearance of the parts, and since it’s an integral part of the aluminum, it will never flake off.

Stainless Steel Inset Hex Head Damper Screws With Flat Black Finish

I replaced the vent damper rivets with 1/4″ x 5/16″ stainless steel screws with an inset hex head, and washers and nuts. The head on these screws matches the size and shape of the original rivets, and the inset hex adds sort of a high-tech look.

The heads of the vent damper screws, the grill strap screws, and the handle screw were sanded lightly and sprayed with high-temp flat black barbecue paint.

Modified Charcoal Grate

Since the charcoal grate is manufactured with gaps that allow charcoal to fall through the grate, I had a welder add additional rods to the left and right of the two parallel braces to close the gaps.

Status Update 9/1/2017

The Two-Tone Blue Bullet popped up online in 2017 when owner Rob Bagby of Swamp Boys BBQ shared an update. Rob says that the original winner of the auction wanted to put this smoker to good use, so in 2004 he gave it to Rob who used it to cook with special education kids that he teaches, and he used it in a few barbecue competitions in Georgia.

This photo shows the cooker at the Kasihta Sand Town Festival, a KCBS sanctioned contest in Cusseta GA on September 2-3, 2005.

At some point Ron passed the smoker along to his nephew, who used it with his Boy Scouts troop in Florida for a number of years. Then it sat unused for a couple of years behind the nephew’s childhood home before Rob reclaimed it in 2015 and cleaned it up in 2017.

“The Two-Tone Blue is now ready for the next adventure, whatever that may be,” Rob wrote in June 2017.

The next thing I knew, in September 2017 the Two-Tone Blue Bullet showed up in a Facebook post by Stephen Lieberman from Georgia, indicating that the cooker was now part of his Weber collection.

What will Stephen do with this cooker? Only time will tell…